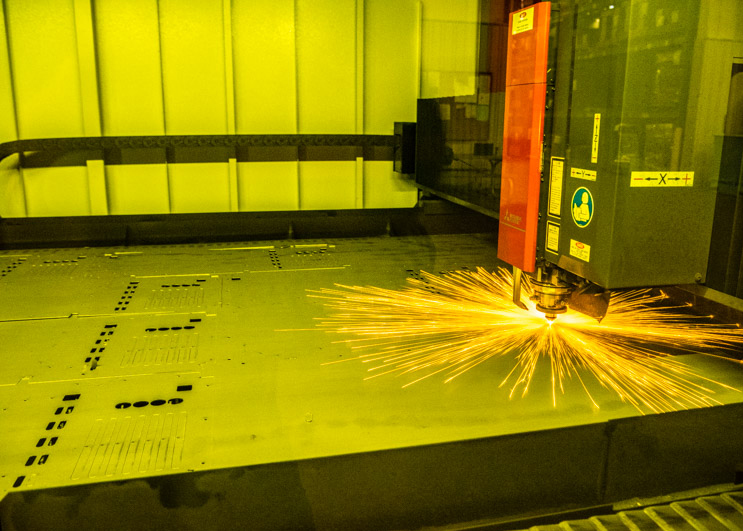

New Laser Added

Announcing the Acquisition of Cutting-Edge CO2 Laser Cutting Technology

We are excited to share a major advancement in our manufacturing capabilities! We have recently acquired state-of-the-art CO2 laser cutting technology that will revolutionize our production process and enhance the quality of our products. This new technology marks a significant milestone in our commitment to innovation and excellence.

Why CO2 Laser Cutting?

CO2 laser cutting has long been celebrated for its precision, efficiency, and versatility. Our latest acquisition is set to elevate our operations by bringing unparalleled advantages to our production line. Here’s what makes this technology a game-changer:

- Exceptional Precision: The CO2 laser cutting system offers remarkable accuracy, with the ability to cut intricate designs and detailed patterns with millimeter precision. This precision ensures that every component meets the highest standards of quality, minimizing waste and maximizing efficiency.

- Versatile Material Processing: Our new CO2 laser cutter is capable of handling a wide range of materials, including metals, plastics, wood, and glass. This versatility allows us to offer a broader array of products and services, catering to diverse industries and applications.

- Faster Production Speeds: The advanced technology of the CO2 laser cutter significantly increases cutting speeds compared to traditional methods. This efficiency not only accelerates our production timelines but also helps us meet tight deadlines and respond swiftly to customer demands.

- Superior Edge Quality: The laser cutting process results in clean, smooth edges with minimal burrs or distortions. This superior edge quality reduces the need for secondary finishing processes, cutting down on labor and material costs while delivering a polished, professional finish.

- Reduced Heat Affected Zone (HAZ): The precision of the CO2 laser cutter minimizes the heat affected zone, which helps in preserving the structural integrity of the material being cut. This feature is crucial for applications requiring high strength and durability.

- Environmental Efficiency: Our new technology aligns with our sustainability goals by reducing material waste and energy consumption. The CO2 laser cutting process is highly efficient, which not only benefits the environment but also contributes to cost savings and operational excellence.

How This Technology Benefits You

With the integration of our new CO2 laser cutting system, we can offer enhanced capabilities and benefits to our clients, including:

- Customization and Flexibility: Our ability to produce highly customized and complex designs means we can better meet your specific requirements and adapt quickly to changing needs.

- Enhanced Product Quality: The precision and quality of the CO2 laser cutting process ensure that your products are crafted to the highest standards, enhancing durability and performance.

- Faster Turnaround Times: Thanks to the increased efficiency and speed of the new technology, we can deliver your orders more quickly, helping you stay ahead in a competitive market.

Looking Forward

We are thrilled about the opportunities this new CO2 laser cutting technology brings and are confident it will drive significant improvements in our manufacturing processes. As we continue to invest in cutting-edge technology and innovations, our goal remains to provide you with superior products and exceptional service.

We invite you to reach out to us to learn more about how this new technology can benefit your projects. Thank you for your continued trust and partnership. We look forward to achieving new heights together!